Products

Online Exporter Fruit Shell Grinder Machine - Pickling and phosphating (boronizing) production line – Fasten

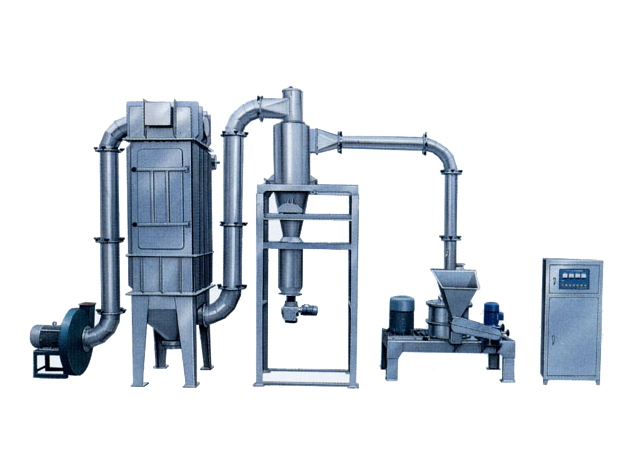

Online Exporter Fruit Shell Grinder Machine - Pickling and phosphating (boronizing) production line – Fasten Detail:

Feature

High production capacity, high efficiency, low consumption, few operation faults and less area requirement, low consumption, high automation.

Parameters

|

1 |

Pay-off: load the wire rod on the production line. |

|

2 |

Water seal & Degreasing: Degreasing and cleaning the wire rods entering the production line to wash away the oily attachments on the surface. |

|

3 |

Water seal & Degreasing: Degreasing and cleaning the wire rods entering the production line to wash away the oily attachments on the surface. |

|

4 |

Rinsing: Clean the wire rod after degreasing to remove oils. |

|

5 |

Pickling: Remove the oxide layer on the surface of the wire rod, chemical reaction. |

|

6 |

Rinsing: Clean the wire rod after pickling to remove some residual acid and ferrous iron. |

|

7 |

Rinsing: Further cleaning the wire rod surface. |

|

8 |

High pressure spraying: To perform high-pressure washing on the inner and outer surfaces of the wire rod to remove residual acid and ferrous ions on the surface of the wire rod. |

|

9 |

Surface conditioning: Remove most of the ferrous iron and iron compounds remaining on the surface of the wire rod after pickling; Facilitate the formation of phosphating film with fine and compact grains; Improve the adhesion of phosphate coating. |

|

10 |

Phosphating: Form a phosphate film on the surface of the wire rod. |

|

11 |

High pressure spraying: Remove the phosphating liquid and slag on the wire rod after phosphating. |

|

12 |

Rinsing: Remove the phosphating liquid and slag on the surface of the wire rod after spraying. |

|

13 |

Boronizing: Neutralize the residual acid on the surface of the wire rod. Formed a loose and porous puffed coating on wire rod surface convenient for wire drawing. |

|

14 |

Liming: Neutralize the residual acid on the surface of the wire rod. Formed a liming coating on wire rod surface convenient for wire drawing. |

|

15 |

Saponification: Saponify the surface of the wire rod. |

|

16 |

Drying: Dry the surface of the wire rod. |

|

17 |

Take-up: Unload the processed wire rods from the production line. |

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for Online Exporter Fruit Shell Grinder Machine - Pickling and phosphating (boronizing) production line – Fasten , The product will supply to all over the world, such as: Cyprus, Vietnam, Jamaica, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

Write your message here and send it to us