Products

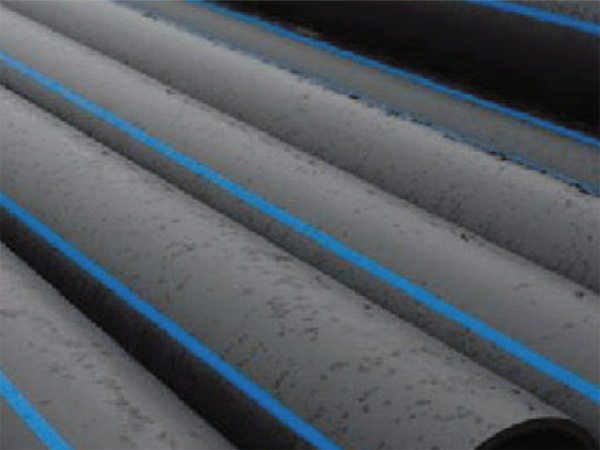

High Reputation Big Diameter Cable Machine - Polyethylene(PE) pipe for water supply infrastructure – Fasten

High Reputation Big Diameter Cable Machine - Polyethylene(PE) pipe for water supply infrastructure – Fasten Detail:

Features

Fasten Hopesun Polyethylene (РЕ) pipes are produced from high-density polyethylene resin, and the production process is strictly organized in accordance with GB/T related standards. The product does not contain heavy metal additives, does not scale, does not breed bacteria, does not cause secondary pollution to the transmission medium, and has good chemical stability.

PE pipe has good heat resistance and cold resistance, high rigidity and toughness, good physical and mechanical properties, impact resistance, strong shock resistance, flexibility and twisting performance, and adapts to а wide range of environmental changes. The РЕ pipe welding process is simple, and the mature welding technology ensures high interface strength, so the construction is convenient and the overall project cost is low.

The smooth inner wall of the РЕ pipe and the non-adhesive characteristics of the material itself determine the higher conveying capacity of the product, so the transmission energy consumption is lower.

1.Non-toxic: no addition of heavy metallic salt stabilizer, would not be covered with dirt or contaminated by bacterium. No second pollution of fungus and bacterium and so on.

2.Corrosion Resistant: resist chemical mediator, no electrochemical corrosion.

3.Corrosion Resistant: corrosion resistance of chemical mediator, no electrochemical corrosion.

4.Low friction drags: smooth interior walls lead to low friction drag.

5.Excellent Flexibility: can be coiled.

6.Excellent workability: be convenient for transporting and installing because of light weight.

7.Longevity: more than 50 years under proper use.

8.Various Joint Availability: butt fusion joint and electrofusion joint available to make sure the identity of interfaces, structure.

Technical Parameters

|

Nominal wall thickness Unit: mm |

||||||||

|

Nominal outer diameter |

SDR9 |

SDR11 |

SDR13.6 |

SDR17 |

SDR21 |

SDR26 |

SDR33 |

SDR41 |

|

Pipe series |

||||||||

|

S4 |

S5 |

S6.3 |

S8 |

S10 |

S12 |

S16 |

S20 |

|

|

PE80 nominal pressure MPa |

||||||||

|

1.6 |

1.25 |

1.0 |

0.8 |

0.6 |

0.5 |

0.4 |

0.32 |

|

|

PE100 nominal pressure MPa |

||||||||

|

2.0 |

1.6 |

1.25 |

1.0 |

0.8 |

0.6 |

0.5 |

0.4 |

|

|

16 |

2.3 |

- |

- |

- |

- |

- |

- |

- |

|

20 |

2.3 |

2.3 |

- |

- |

- |

- |

- |

- |

|

25 |

3.0 |

2.3 |

2.3 |

- |

- |

- |

- |

- |

|

32 |

3.6 |

3.0 |

2.4 |

2.3 |

- |

- |

- |

- |

|

40 |

4.5 |

3.7 |

3.0 |

2.4 |

2.3 |

- |

- |

- |

|

50 |

5.6 |

4.6 |

3.7 |

3.0 |

2.4 |

2.3 |

- |

- |

|

63 |

7.1 |

5.8 |

4.7 |

3.8 |

3.0 |

2.5 |

- |

- |

|

75 |

8.4 |

6.8 |

5.6 |

4.5 |

3.6 |

2.9 |

- |

- |

|

90 |

10.1 |

8.2 |

6.7 |

5.4 |

4.3 |

3.5 |

- |

- |

|

110 |

12.3 |

10.0 |

8.1 |

6.6 |

5.3 |

4.2 |

- |

- |

|

125 |

14.0 |

11.4 |

9.2 |

7.4 |

6.0 |

4.8 |

- |

- |

|

140 |

15.7 |

12.7 |

10.3 |

8.3 |

6.7 |

5.4 |

- |

- |

|

160 |

17.9 |

14.6 |

11.8 |

9.5 |

7.7 |

6.2 |

- |

- |

|

180 |

20.1 |

16.4 |

13.3 |

10.7 |

8.6 |

6.9 |

- |

- |

|

100 |

22.4 |

18.2 |

14.7 |

11.9 |

9.6 |

7.7 |

- |

- |

|

225 |

25.2 |

20.5 |

16.6 |

13.4 |

10.8 |

8.6 |

- |

- |

|

250 |

27.9 |

22.7 |

18.4 |

14.8 |

11.9 |

9.6 |

- |

- |

|

280 |

31.3 |

25.4 |

20.6 |

16.6 |

13.4 |

10.7 |

- |

- |

|

315 |

35.2 |

28.6 |

23.2 |

18.7 |

15.0 |

12.1 |

9.7 |

7.7 |

|

355 |

39.7 |

32.2 |

26.1 |

21.1 |

16.9 |

13.6 |

10.9 |

8.7 |

|

400 |

44.7 |

36.3 |

29.4 |

23.7 |

19.1 |

15.3 |

12.3 |

9.8 |

|

450 |

50.3 |

40.9 |

33.1 |

26.7 |

21.5 |

17.2 |

13.8 |

11.0 |

|

500 |

55.8 |

45.4 |

36.8 |

29.7 |

23.9 |

19.1 |

15.3 |

12.3 |

|

560 |

62.5 |

50.8 |

41.2 |

33.2 |

26.7 |

21.4 |

17.2 |

13.7 |

|

630 |

70.3 |

57.2 |

46.3 |

37.4 |

30.0 |

24.1 |

19.3 |

15.4 |

|

710 |

79.3 |

64.5 |

52.2 |

42.1 |

33.9 |

27.2 |

21.8 |

17.4 |

|

800 |

89.3 |

72.6 |

58.8 |

47.4 |

38.1 |

30.6 |

24.5 |

19.6 |

|

900 |

- |

81.7 |

66.2 |

53.3 |

42.9 |

34.4 |

27.6 |

22.0 |

|

1000 |

- |

90.2 |

72.5 |

59.3 |

47.7 |

38.2 |

30.6 |

24.5 |

|

1200 |

- |

- |

88.2 |

69.9 |

57.2 |

45.9 |

36.7 |

29.4 |

|

1400 |

- |

- |

102.9 |

82.4 |

66.7 |

53.5 |

42.9 |

34.3 |

|

1600 |

- |

- |

117.6 |

94.1 |

76.2 |

61.2 |

49.0 |

39.2 |

|

1800 |

- |

- |

- |

105.9 |

85.7 |

69.1 |

54.5 |

43.8 |

|

2000 |

- |

- |

- |

117.6 |

95.2 |

76.9 |

60.6 |

48.8 |

|

2250 |

- |

- |

- |

- |

107.2 |

86.0 |

70.0 |

55.0 |

|

2500 |

- |

- |

- |

- |

119.1 |

95.6 |

77.7 |

61.2 |

|

Note: The product implements this standard GB/T13663.2-2018 |

||||||||

Product detail pictures:

Related Product Guide:

Our purpose is to fulfill our clients by offering golden company, great price and premium quality for High Reputation Big Diameter Cable Machine - Polyethylene(PE) pipe for water supply infrastructure – Fasten , The product will supply to all over the world, such as: Ottawa, America, Adelaide, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.